"If you can't fix it with a hammer, you've got an electrical problem"

Well it looks like we've got an electrical problem then. After a long spell of debugging communication issues between the Arduino and the BeagleBone, we had run into another challenge: the GPS.

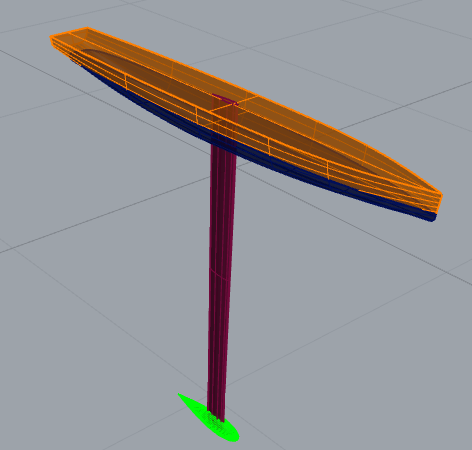

Pictured above the team has taken the

Arctica (the boat) and her sensors outdoors to see if we can get a fix with the GPS. The GPS is the eyes of

Arctica and without it she would loose all sense of purpose in her life. At the time we couldn't get the GPS to pick up any satellites and thus couldn't get a fix. Either the GPS itself (hardware) or somewhere within the many lines of code that Daniel has hand crafted (software), something wasn't working.

After some background research on the GPS and how it works, along with a new GPS, we managed to get a proper fix. However nothing is ever easy and we are now faced with the task of sending the way points from the Arduino to the BeagleBone for course plotting. This involves setting up the "mailing procedure" of the data. This procedure lets the BeagleBone know what it should be receiving (GPS coordinates) and tells it not to sign for the parcel if it thinks it's getting garbage data.

Guess we'll be giving the hammer a rest for a bit. Although some days I'm sure Dan feels that a little persuasion here and there wouldn't hurt.

.jpg)