Friday 30 November 2012

Special Thanks to ...

We thank Rutter INC. for sponsoring us at the Top Gallant Level! We are proud to be sponsored by such a leader in marine electronics and communication systems. Their in-kind donations will be an asset to the team in the build of the next boat.

Tuesday 30 October 2012

Special Thanks to Dr. Janna Rosales

Above: Dr. Rosales speaking at Ted Talk

"Special Thanks to Dr. Janna Rosales for allocating time from her tightly scheduled engineering ethics class to allow the MUN Sailbot Team to speak about recruitment on Wednesday and Thursday of this week."

Friday 26 October 2012

Like this...But smaller!!

The design for the next generation of MUN SailBOT racing machine is underway. Though the team is spread across the country, we are laying the groundwork for the new vessel. The vessel will be a trimaran with a articulating wing sail designed to go really, really fast! We will be working with Rhino for the 3-D modeling, CAD for the general arrangement and GHS or Maxsurf for the hydrostatics. Over the next few months we will spiral in on a final design, and -with our fingers crossed - pull the carbon fiber hull next semester. More design posts to come!

Wednesday 24 October 2012

On processors

Our current electronics setup is run using a Real Time Operating System from UVic running on an ATMEGA 1280. Drivers have been written - the system works - but is rather heavily taxed by the number of things which it must do. We would like to do path planning, more sensor processing and more intelligent decision making. To that end we've been discussing the use of a more powerful processor to add the higher level of control which is the next step in our development. We chose the well maintained Arduino platform for it's ease of use, its flexibility, the soundness of hardware and most importantly the community which surrounds it. The Raspberry Pi is now a hit in the hobbyist community which sports a powerful ARM processor, a bunch of IO, several projects which integrate it with our current processor and a low cost. So as mentioned in the previous post we've purchased a couple to try them out.

Check back for updates.

[-Jordan]

Wednesday 10 October 2012

The New CPU

The new cpu of the new boat has been ordered!!!! The Raspberry Pi shown above is a Linux based micro-controller that is more computer than micro-controller. This cpu contains an ARM-1176JZFS processor with floating point, running at 700Mhz, and a Videocore 4 GPU. The GPU is capable of BluRay quality playback, using H.264 at 40MBits/s. It has a fast 3D core accessed using the supplied OpenGL ES2.0 and OpenVG libraries....TRANSLATION FOR NON-COMPUTER PEOPLE.... WE BOUGHT A WEAPON OF A COMPUTER BRAIN FOR UNDER $40!!!!!!!!!!!!!! Yes, that's right under $40!

Click here for more information.

Special Thanks to ...

We thank Notus Electronics Ltd. for sponsoring us at the Top Sail Level! We are proud to be sponsored by such a leader in Marine Sensor technology. The company has given both in-kind donations and money towards the new boat, which is greatly appreciated by all members of the team.

Wednesday 3 October 2012

On blogging

For those who require a little more control, are afraid of storing their info here, relying on a free service or just want to use something a little more open I would suggest the open source Wordpress package, available at http://wordpress.org/download/. Installed and configured in minutes it's a fast way to get a professional quality blog started.

[-Jordan]

Wednesday 26 September 2012

New Years

The New Year, the start of a new calendar, is time for making changes with a fresh start. To many it occurs on January 1st, but to those who follow a University Calendar it is clearly marked as taking place on a Wednesday in early September. Keeping with the fall festivities around the university, Sailbot has been working away on their New Year's resolutions, new developments and plans for upcoming semesters. Paperwork is being filed, logos have been updated to more robust vector formats, advertising material is being created and events are being planned. Anybody who has been fond of the team or is looking to join should drop us a line, especially if they are interested in some Sailbot-branded material. Or, if you feel like a chat, stop into the AOSL (EN-1035E), we usually meet at 6 each Wednesday.

On a related note I would suggest that anyone looking for a professional level graphic design package on the cheap should check out the tools GIMP and Inkscape for scalar and vector design respectively. They are quite powerful, well maintained and documented but most importantly they are Open Source projects - worth checking out.

On a related note I would suggest that anyone looking for a professional level graphic design package on the cheap should check out the tools GIMP and Inkscape for scalar and vector design respectively. They are quite powerful, well maintained and documented but most importantly they are Open Source projects - worth checking out.

[-Jordan]

Labels:

Advertising,

blog,

Development,

GIMP,

Inkscape,

Shirts,

SVG

Wednesday 8 August 2012

Changing of the Guard

We're wrapping up the summer semester here at Memorial. It's been a great summer and everyone is packing up to go to their Fall Co-op placements.

In a dramatic turn of events, and several phone calls later, our boat may very well be on a truck tomorrow and on its way back home. Turns out summer is a popular time for vacations.

We also have some lovely gifts done up for our sponsors from the past year. Thank you everyone who contributed to make this project possible. Keep an eye on your mailbox for something from MUN Sailbot.

The next few weeks we will be gearing up for Fall recruitment and fundraising. If you know of anyone or are interested yourself in being involved keep an eye out as we are planning a few events.

In completely unrelated news, sailing anarchy had this RC boat up a while back. Looks a bit like Arctica with a few differences.

In a dramatic turn of events, and several phone calls later, our boat may very well be on a truck tomorrow and on its way back home. Turns out summer is a popular time for vacations.

We also have some lovely gifts done up for our sponsors from the past year. Thank you everyone who contributed to make this project possible. Keep an eye on your mailbox for something from MUN Sailbot.

The next few weeks we will be gearing up for Fall recruitment and fundraising. If you know of anyone or are interested yourself in being involved keep an eye out as we are planning a few events.

In completely unrelated news, sailing anarchy had this RC boat up a while back. Looks a bit like Arctica with a few differences.

Friday 13 July 2012

Sailbot 2012 in Vancouver

We are back from Vancouver safe and sound. Those that drove out to Vancouver had a very fast drive. Driving from St. john's to Vancouver in four and half days. The total distance is close to 8000 km and includes a 4-6 hour ferry.

The competition was a great experience for the team. While we beat our score from last year, we got last place overall. However, the boat was durable and performed well under all conditions. We now have a stable platform to test code with and the mechanical and naval students can focus on a whole new build. Many of the systems which have been worked out on this build are transferable to any new boats we build. The biggest take away from the competition is to have the boat in the water early, have it in the water lots and streamline your software development cycle.

We are now waiting for the boat to finish shipping back to St. John's and revamping our fund-raising strategies for the coming year. It is an exciting time to be involved in the Sailbot class as teams are getting close to perfect scores. The competition is prime to evolve. A big congratulations to the UBC team for winning Sailbot 2012.

| Arctica Rounding the Mark |

Sunday 27 May 2012

May 27th Long Pond Test

Today we took our 4th time field test in the long pond.

In the test, the actuators (winches and rudders) were working perfectly.

RC mode are well performed.

In the autonomous aspect, the boat responsed, but still needs to be implemented.

The hull is totally dry inside after the test. The boat is perfectly sealed.

Need to be done:

The jib winch need to be investigated, the motor perform weird after the boat is back.

Cheers,

MUN Sailbot.

In the test, the actuators (winches and rudders) were working perfectly.

RC mode are well performed.

In the autonomous aspect, the boat responsed, but still needs to be implemented.

The hull is totally dry inside after the test. The boat is perfectly sealed.

Need to be done:

The jib winch need to be investigated, the motor perform weird after the boat is back.

Cheers,

MUN Sailbot.

Monday 21 May 2012

May 13th Long Pond Test

First water test succeed!!!!!!!!!!!!

We are so excited to launch our 2012 boat, F' Arctica.

Compared to the last year's boat, the performance of this boat is significantly improved. The boat is lighter, faster, and easier to control.

Top speed: 3.4 knots.

Wednesday 2 May 2012

Shorts! and not because its summer.

So it's finally may in St. John's and to say hello it snowed all day. Lovely slushy stuff. So no wearing shorts.

However, we have other shorts. The electrical kind. Luckily our power supply is smart and decides to not turn on when there is a dead short. So for future reference, all you board designers who think you are clever and add power and ground planes on the top and bottom of your boards. Use nylon stand-offs or at least leave enough room that the aluminum doesn't cut through the solder mask and make your board think it should be summer time.

However, we have other shorts. The electrical kind. Luckily our power supply is smart and decides to not turn on when there is a dead short. So for future reference, all you board designers who think you are clever and add power and ground planes on the top and bottom of your boards. Use nylon stand-offs or at least leave enough room that the aluminum doesn't cut through the solder mask and make your board think it should be summer time.

Sunday 22 April 2012

Crunch Time

We're getting close to our in water deadline of April 28th and here is another update. Our motors have finally arrived after bouncing around Florida, Texas, Quebec, Texas again, Nova Scotia and finally to us!

They are shiny aren't they. They will go into our new actuator design which is completely waterproof, capable of up to 3 Nm and around 60 RPM. Our test actuator has just finished being assembled and tested and the rest are being machined right now by Engineering Techinical Services, which has generously donated the machining time. Thanks Tech Services!

In other news, the spreaders, shrouds and other rigging are nearing completion. All of the pieces being attached to the mast this year are being placed on sleeves which fit over the mast. This allows us to remove them for shipping, replace them if needed and keeps the structural aspects in tact. The last pieces are being bagged right now.

|

| Motors Arrive |

In other news, the spreaders, shrouds and other rigging are nearing completion. All of the pieces being attached to the mast this year are being placed on sleeves which fit over the mast. This allows us to remove them for shipping, replace them if needed and keeps the structural aspects in tact. The last pieces are being bagged right now.

|

| Spreaders |

Yes, that is a garbage bag and no that is not what we have been bagging with. We use much more sophisticated milk bags from Tim Hortons. EconoBag from and mastic tape helps too.

|

| Thuggin |

Monday 16 April 2012

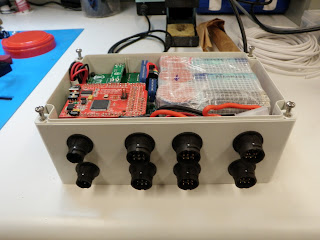

Electronics Box

One of our problems last year was our power connections from the batteries to the everything else got wet and shorted. There was lots of green corrosion and needless to say a complete lack of power to do other things, like drive motors.

This year we are moving our batteries inside a waterproof (IP67+) box along with the electronics. All of the connections are made through circular connectors which have sealing glands around the wires and face seals. They're also made of plastic and quite light.

We had a setback a few weeks ago when after working on getting the wiring set up all of the connectors were left in a box along with the heat gun and heat shrink. Unfortunately, the resident lab thief decided the heat gun would be lovely in his personal collection (no joke). All of our connectors were stolen. A quick call to Tyco Electronics, however, and they agreed to send us replacements. Thanks TE!

Another change this year has been to change the communication from the main controller to the motor controllers to I2C. This change allows for easy expansion. If we ever needed more motors we just add another board to the stack. Right now we can control 4 motors using PID loops with quadrature feedback. The motor drivers are rated to 12A without heatsinks and can operate up to 16V (we run at 12V). There are two Arduino pro minis on the board and each one is responsible for two motors. This division allows you to actually expand the system two motors at a time. The motor controllers provide current feedback which we use to limit the torque output (so we don't break the boat when something jams). The best part is that all the code is updated too and it works. Check out the repo here.

Stay tuned for more updates as we ramp up this week getting ready for first sea trials as the ice is off the lakes now!

This year we are moving our batteries inside a waterproof (IP67+) box along with the electronics. All of the connections are made through circular connectors which have sealing glands around the wires and face seals. They're also made of plastic and quite light.

|

| Electrical box with circular connectors installed and motor driver board in place |

Another change this year has been to change the communication from the main controller to the motor controllers to I2C. This change allows for easy expansion. If we ever needed more motors we just add another board to the stack. Right now we can control 4 motors using PID loops with quadrature feedback. The motor drivers are rated to 12A without heatsinks and can operate up to 16V (we run at 12V). There are two Arduino pro minis on the board and each one is responsible for two motors. This division allows you to actually expand the system two motors at a time. The motor controllers provide current feedback which we use to limit the torque output (so we don't break the boat when something jams). The best part is that all the code is updated too and it works. Check out the repo here.

Stay tuned for more updates as we ramp up this week getting ready for first sea trials as the ice is off the lakes now!

|

| Yeah, It's a tight fit |

Wednesday 21 March 2012

Electronics Rev2

We've recently put together our new electronics package. It is essentially a breakout board for all of the different off the shelf boards we use. Check it out! It has a Seeedstudio Arduino Mega as the master controller, a 3.5A 5V switching regulator from Pololu, SD Card data logging, 4x 12A motor controllers. The motor controllers are controlled by two Arduino Pro Mini's (2 motor controllers to each mini) which take quadrature encoder signals as feedback for motor position and current feedback for torque limiting and control. Big improvement over our previous protoboard ratsnest.

Our second generation wind sensor is almost put together as well. It uses a AS5040 magnetic encoder chip. So far the whole thing weighs less than 15g. (ignore the mastic tape I needed something to hold the vane on temporarily) It outputs a pulse at 1kHz equal with the width equal to the orientation of the magnet attached to the wind vane shaft.

Monday 5 March 2012

Actuator test

Development of new actuators is underway. An implementation of our shaft using aluminum resulted in some shearing and sad team members. So we remade it with stainless steel and new grub screws. Here's a test of the build that used a rapid-prototyped casing and a shaft which did not fail:

(Note: Musical tastes are those of the fabrication team and are not necessarily those expressed or endorsed by this blog.)

Friday 24 February 2012

Shipside electronics have been moved to new PCBs

Due to their added weight and difficult wiring the protoboard versions of the ship-side mother boards have finally been drafted in Eagle and sent to Fusion PCB for fulfillment. Having several PCBs means fast repairs are possible on competition day without tedious creation of a replacement board, many grams of insulated wire have been removed from our heavy build and a digital copy makes tracking changes easier. Design continues to keep the motor and controller boards separate for modular development or repair and has also retained the preference for readily-replaceable daughter boards as modifications will continue to be made.

Several issues with the use of customized optical rotary encoders for our actuators have prompted a move to a magnetic design. Hall-effect sensors and neodymium magnets give us data at an acceptable rate and allow for better mounting. A similar hall-effect sensor was used for the wind sensor. PCBs for these components already been received and we are quite happy with the results.

Not ones to waste space and add weight some excess space on these boards was used to create Sailbot key fobs, the last few of which can be purchased to help pay for future PCB orders, so give us a shout us if you'd like one. As always, to anyone interested, feel free to use these files in your own builds or contact us at munsailbot.com or via facebook for more information.

[Eagle files: http://www.filehosting.org/file/details/315904/board_and_schematics.zip ]

Thanks to everyone who worked on these designs!

Several issues with the use of customized optical rotary encoders for our actuators have prompted a move to a magnetic design. Hall-effect sensors and neodymium magnets give us data at an acceptable rate and allow for better mounting. A similar hall-effect sensor was used for the wind sensor. PCBs for these components already been received and we are quite happy with the results.

Not ones to waste space and add weight some excess space on these boards was used to create Sailbot key fobs, the last few of which can be purchased to help pay for future PCB orders, so give us a shout us if you'd like one. As always, to anyone interested, feel free to use these files in your own builds or contact us at munsailbot.com or via facebook for more information.

[Eagle files: http://www.filehosting.org/file/details/315904/board_and_schematics.zip ]

Thanks to everyone who worked on these designs!

[-Jordan]

Improvements to hatch design

The 2011 competition in Annapolis was a huge milestone for MUN Sailbot; it was also the first time when the boat received a live, all systems go, testing. Through this testing some design features where highlighted as areas that needed refinement. One such area was the deck hatches.

The deck hatches have undergone various prototypes and design modifications to arrive at the stage they are now. Currently we are glassing what we hope to be the final design for both the fore and main hatches. The hatches should be easily removable while at the same time maintaining a sleek, flush deck profile to keep the Misses looking sharp.

We have also redesigned the interior to accommodate fewer, smaller hatches. This further reduces the chances of water entering the boat and reduces time spent laying up custom sized hatches.

With these two modifications, we are confidant that our interior systems will remain protected from the elements; a major step forward when considering long distance, un-aided ocean transit.

[Content by Liam, photos by Ryan] |

| Hatch in development |

|

| View as will be seen from deck. |

Subscribe to:

Posts (Atom)